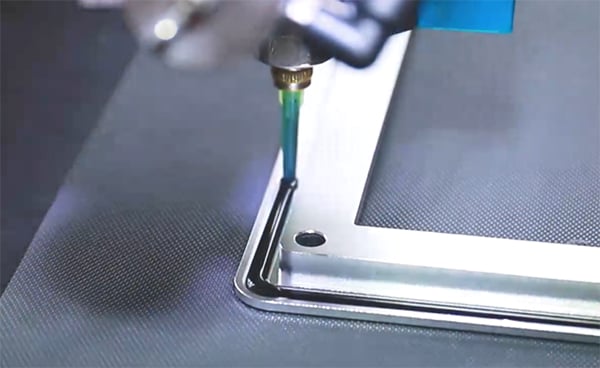

Plastic products often involve applying gaskets to intricate contours and surfaces. Our form-in-place foam gasket machine is able to accurately control the discharge quantity of material. Facilitated by CNC multi-axis programming, the machine ensures the precise mixing and placement of foam gaskets into or onto the narrow grooves of plastic surfaces. Within a single duty cycle, the foam gaskets undergo air curing and achieve a resilience of over 95% (DVR < 5%). This enables the frequent opening and closing of the plastic product while maintaining a consistently high level of sealing efficiency.

Our precise and stable formed-in-place foam gasketing machine operates seamlessly in narrow grooves, making it perfectly suited for complicated workpieces. The gasketing process ensures that sealed items are thoroughly protected against moisture, corrosion, and dust.

How can we help You?

Suitable for various gasket sealants and adhesives with different properties, the three-component drum pump supply system features simple and user-friendly design and exceptional flexibility of meeting various gasketing demand.

The automatic drum dispensing system can accommodate up to 55 gallons (approximately 200 kg of materials), featuring automatic cover lifting and an automated system for feeding, stirring, and supplying materials, all powered pneumatically for energy efficiency.

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.