We specialize in manufacturing and supplying form-in-place foam gasket machines for the advanced sealing of EV battery packs, ensuring comprehensive protection against moisture, corrosion, and dust, thereby enhancing their stability and longevity.

Our cutting-edge technology and deep industry expertise position us as the preferred partner within the new energy sector for sealing solutions tailored to mobile energy and battery applications. Apart from form-in-place gasket applying machines, our offerings also include a conductive coating, thermal interface materials, adhesives, and liquid sealants, all designed to deliver uninterrupted protection for the battery pack. We employ an air-curing, two-component polyurethane foam gasket to seal the batteries effectively, safeguarding them against moisture, corrosion, and dust. These materials are not only resilient against vibration but also withstand extreme temperatures and harsh chemicals, contributing significantly to the battery's durability. As a trusted partner, we are dedicated to delivering solutions that ensure superior battery performance under any condition, reaffirming our commitment to excellence and customer satisfaction in the dynamic landscape of new energy.

How can we help You?

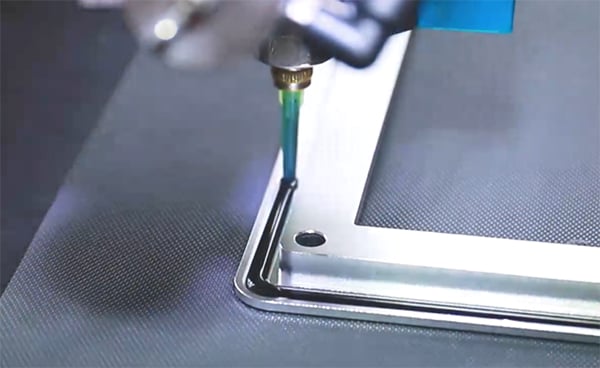

Suitable for various gasket sealants and adhesives with different properties, the three-component drum pump supply system features simple and user-friendly design and exceptional flexibility of meeting various gasketing demand.

The automatic drum dispensing system can accommodate up to 55 gallons (approximately 200 kg of materials), featuring automatic cover lifting and an automated system for feeding, stirring, and supplying materials, all powered pneumatically for energy efficiency.

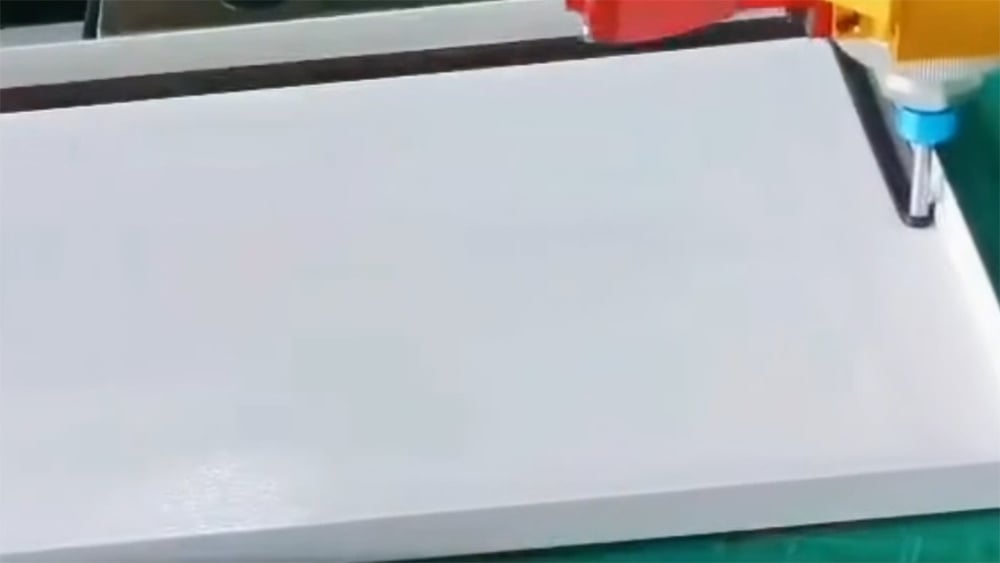

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.