Explosion-proof cabinets, designed for storing or processing volatile substances like chemicals and gases, necessitate impeccable sealing to mitigate risks to the external environment. Key challenges for foam gasket machines include ensuring safety, resistance to corrosion and chemicals, material adaptability, processing control, and endurance to high temperatures and pressures, alongside maintenance demands.

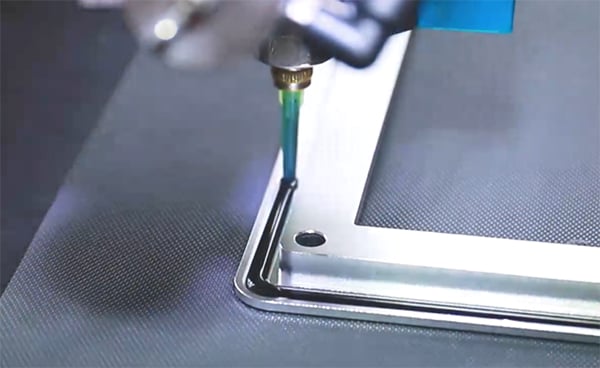

Our formed-in-place foam gasket machine employs materials resistant to corrosion and chemicals, guaranteeing the stability of foam gaskets in environments with high temperatures and moisture. Our FIPFG gasketing technology ensures an even distribution of gaskets onto workpieces in the precise amounts required for optimal sealing effect. Additionally, we offer comprehensive maintenance solutions to sustain the long-term performance of the foam gaskets and ensure the safety of the explosion-proof cabinets.

How can we help You?

Suitable for various gasket sealants and adhesives with different properties, the three-component drum pump supply system features simple and user-friendly design and exceptional flexibility of meeting various gasketing demand.

The automatic drum dispensing system can accommodate up to 55 gallons (approximately 200 kg of materials), featuring automatic cover lifting and an automated system for feeding, stirring, and supplying materials, all powered pneumatically for energy efficiency.

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.