When it comes to gasketing in the lighting industry, traditional gasket applying machines often encounter issues such as inconsistent application, inadequate adhesion, lack of durability, and poor adaptability. Additionally, materials may adhere too strongly to surfaces, complicating removal and maintenance processes. To address these challenges, manufacturers are prompted to refine their designs and materials, specifically focusing on foam gaskets, to improve the stability and precision of their machines.

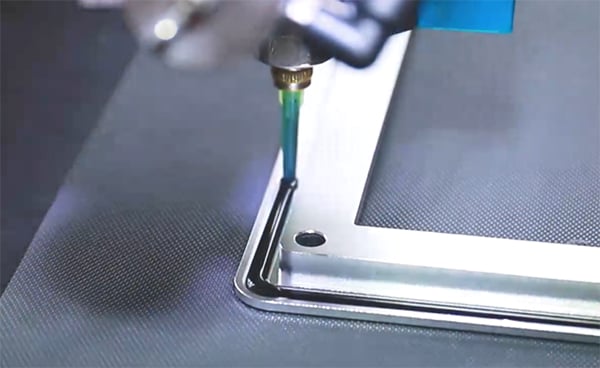

Compared with traditional machines, our formed-in-place foam gasket machine provides a more economical and comprehensive gasketing solution covering both gasketing devices and materials. The foam gaskets we've engineered are designed to fully meet your requirements, allowing for direct application to workpieces. Furthermore, our formed-in-place gasket dispensing machine ensures the stable dispensation of foam gaskets in the precise quantities needed, streamlining the gasketing process for enhanced efficiency and effectiveness.

How can we help You?

Suitable for various gasket sealants and adhesives with different properties, the three-component drum pump supply system features simple and user-friendly design and exceptional flexibility of meeting various gasketing demand.

The automatic drum dispensing system can accommodate up to 55 gallons (approximately 200 kg of materials), featuring automatic cover lifting and an automated system for feeding, stirring, and supplying materials, all powered pneumatically for energy efficiency.

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.