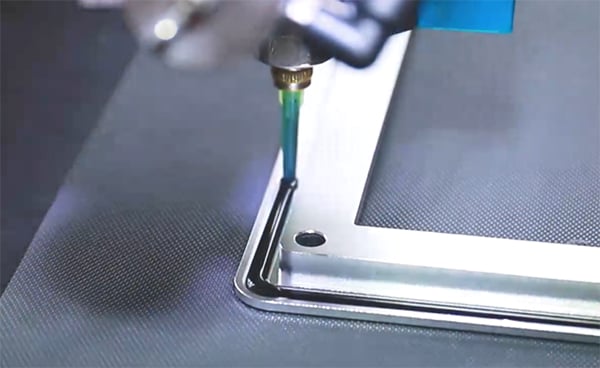

Gasketing and sealing machines are widely applied in the Cleanroom Door sector, mainly for better air quality and insulation. Good sealing can improve the durability, adaptability, and installation accuracy, thus enhancing the overall performance of the door.

Our formed-in-place foam gasket machine offers a comprehensive solution that guarantees accurate material application, ensuring smooth surfaces and seamless flow at coupling points with excellent material resilience. It supports a wide range of gasketing materials, making it adaptable to doors made from various materials. The machine's water resistance rating of up to IP 67, combined with its automatic operation, ensures both quality and consistency in every product. We are dedicated to delivering reliable and efficient sealing and gasketing solutions tailored to meet the demands of the cleanroom door industry.

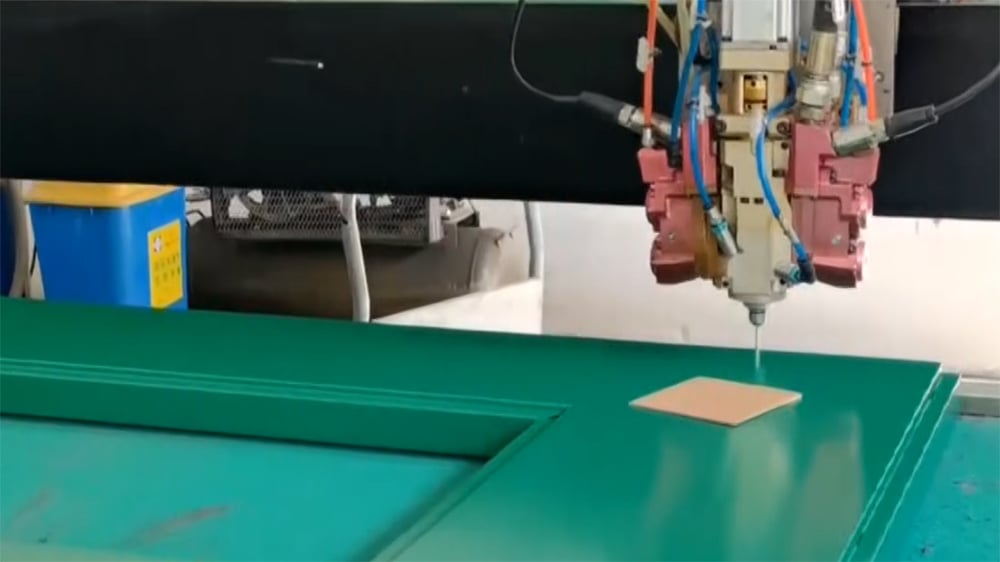

Our fleet of formed-in-place foam gasket machines, including the SJ-503 model, boasts an extensive travel range of 2250×1250×200 mm, catering to a variety of gasketing requirements for cleanroom doors. With the capability to dispense foam gaskets ranging from 5mm to 30mm, the SJ-503 model is ideally suited for cleanroom door sealing applications. For products requiring longer foam gaskets, we offer customization services to perfectly meet your needs.

How can we help You?

Our control system seamlessly integrates with the six-axis robot adhesive dispensing system, which supports one-, two-, and multi-component polymer materials with a wide range of viscosities, ensuring optimal sealing and gasketing performance.

The water-cooled storage tank is an innovative storage device designed specifically for prolonged high-heat settings. It can keep the gasket sealants and adhesives at desired temperatures, thereby ensuring product quality and consistency.

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.